Location: Machining

Machining

Although not our main setting, we offer a range of oil and cutting fluid cleaning equipment from suppliers of our other equipment.

For separating heavy material from the main body of fluid. These do not have the capability to separate a light phase.

Oilybits Coolant / Cutting Fluid, Tramp Oil Separating & De-Odourising System

For separating tramp oil, with an optional Ozone Generator for disinfection and deodorisation.

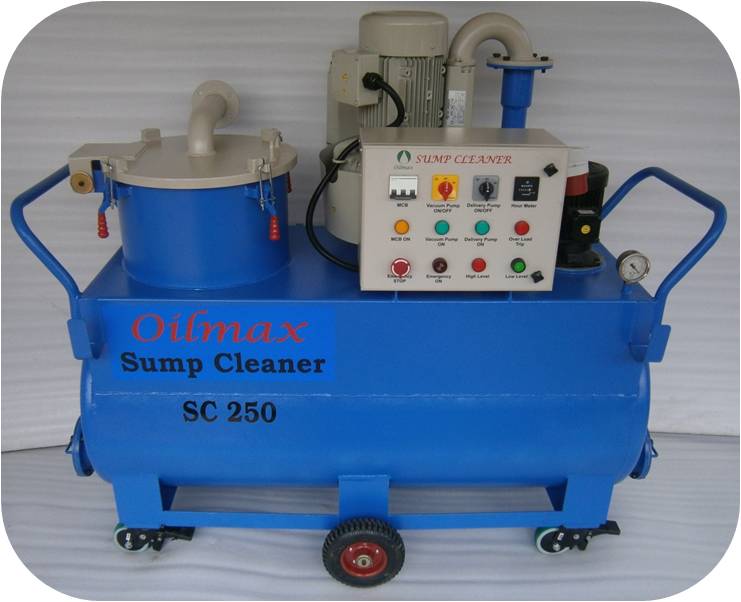

Oilybits Coolant / Cutting Fluid Sump Cleaning System, 50 to 500 Litre Capacity

For evacuating the sump under vacuum, and then returning the fluid from the tank via a filter.

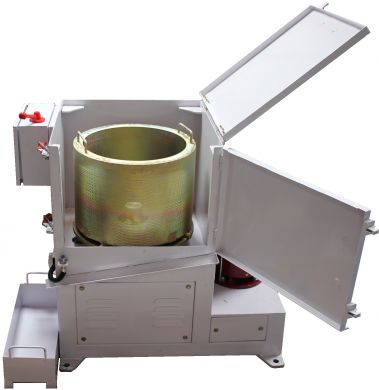

Oilybits OB-45 Perforated Basket Centrifuge / Centrifugal Sieve

For recovering cutting fluid from swarf.

Oilybits Perforated Basket Centrifuge / Centrifugal Sieve, with Automatic Feed Conveyor

Oilybits 80 Ton, Chip / Swarf Compactor, 100 Litre

For compressing swarf / chips into manageable bales. 80 tons of force. Typical compaction ratio 6:1

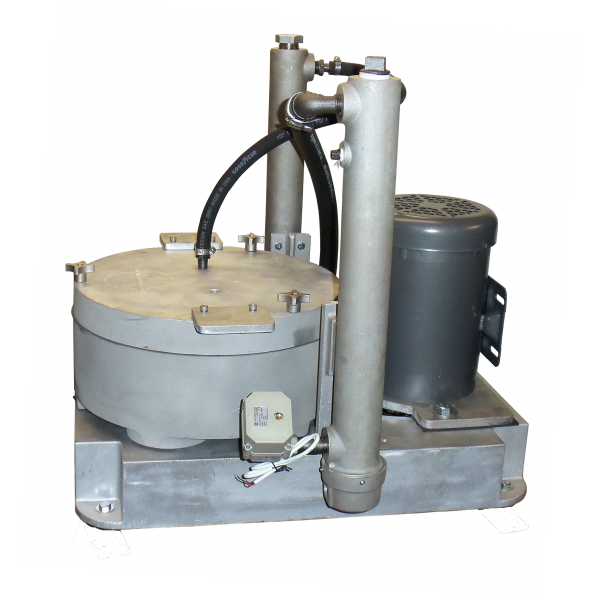

Oilybits Compact Hydraulic Oil Filtration System, for 0.1 Micron Particle & Water Removal

Oilybits Hydraulic Oil Filtration System, for Water and 0.1 Micron Particle Removal

Oilybits Centrifugal Oil Cleaning System (Centrifuge on Trolly), 540 to 9000 Litres Per Hour

For servicing gearboxes and motors, the system evacuates the contents using a self priming pump with lance then returns the clean fluid to the reservoir.

For servicing gearboxes and motors, the system evacuates the contents using a self priming pump and lance.

Some of the common applications for the above oil cleaning equipment:

- Wire Drawing

- Cold Forming

- Fastener Manufacturing

- Heat Treatment

- Bright Bar Manufacturing

- Thread Rolling

- Super Finishing

- Honing

- Grinding

- Gear Boxes

- Cement Mills

- Coal Mills

- Crushers

- Transmissions

- Marine Engines

- Port Equipment

- Mining Equipment

- Diesel Generator Sets