Goldstream AC Industrial Gear Pumps for Fuel & Motor Oils 95 lpm, Cast Iron, Max 200 Celcius

Robust, and reliable Baseplate-Mounted Industrial Gear Pumps.

This Industrial Gear Pump has been designed to be chemically compatible with fluids such as Vegetable Oil, Animal Fats, Motor Oil, Waste Motor Oil, Lubricating Oils, and other medium to high viscosity oils and other non corrosive viscous substances, this does not include oils containing any water, or emulsified water. NOTE: if this pump is used to drain oil from the bottom of a vessel, and that oil contains settled water, the pump will rust solid during rest, if there is any possibiity of the oil tank containing water, then always run the pump through with dry oil after use.

- Internal gears have bearings at both ends to ensure trouble free usage at high speed and under pressure

- Due to the motor being long-coupled to the pump head, this enables the pump to operate at up to 200 Celcius

- Shaft is exposed for efficient cooling, so precautions need to be taken as if it were any other piece of rotating machinery, to avoid material or persons being drawn in

IMPORTANT - Gear pumps cannot pump solid matter such as metal fragments, these will jam the gears and stop the pump, which can damage the motor or blow fuses. If you intend to use the pump for any oil with SOLID particle contamination, then you will need to install an inline filter to protect the pump, or be prepared to dismantle and unblock the pump as required. The pump can handle soft particles and will rapidly grind up soft particle matter such as food debris, fats, greases, etc. If you are likely to be pumping oil with solid particle contamination then we recommend using one of our Flexible Impeller Pumps which can handle very large solids without risking damage to the pumps impeller or motor, though flexible impeller pumps are not good for hot liquids, or pumping in high pressure or vacuum environments, in this scenario this gear pump is better.

Wetted Components| Version | Cast Iron |

| Motor Face | Cast Iron |

| Impellor Case | Cast Iron |

| Impeller Case Seal | Paper Gasket |

| Motor Shaft Seal | Viton |

| Vanes | Not Present |

| Vane Springs | Not Present |

| Rotor / Gear / Impellor | Steel |

| Shaft Key / Nut | Steel |

| Motor Shaft | Hardened Steel |

| Bypass Valve Piston | Steel |

| Bypass Valve Seal | Viton |

| Bypass Valve Spring | Stainless Steel |

Performance| Voltage / Frequency | 115-230vAC 60Hz 1Ph OR 208-230/460vAC 60Hz 3Ph |

| Kw | 3-Ph 2.2 |

| Amps | 28 @ 120V 60Hz, 14 @ 230v 60Hz, 9-8.4/4.2 @ 208-230/460vAC 60Hz |

| RPM | 1Ph = 1725 RPM, 3Ph = 1760 RPM |

| Duty Cycle | Continuous at full flow |

| Cable Length | 0.75m |

| Bypass Valve Y/N | Y, Max. Setting 3.3 Bar. |

| Max Flow (Open Discharge) | 95 LPM @ 1800 RPM nom. |

| Discharge Pressure | Limited to Max. 3.3 Bar by relief valve. |

| Max Suction Lift (Dry) | 4.5 m |

| Max Suction Lift (Wet) | 4.5 m |

| Inlet Fitting | 1.5"NPT Female |

| Outlet Fitting | 1.5"NPT Female |

| Max Particle Tolerance | 200 Micron |

| Max Liquid Temp | 200° |

| Min Liquid Temp | |

| Max Room Temp | 40° |

| Min Room Temp | |

| Thermal Protection Y/N | Y |

| Max Liquid Viscosity | Up to Cold Motor Oil, or similar |

| Ingress Protection | IP44 |

Dimensions| Length | TBC cm |

| Width | TBC cm |

| Height | TBC cm |

| Weight | TBC kg |

| Base Plate | TBC cm |

Shown Below: Internal Gear Mechanism (One bearing removed to expose gear for photograph)

Download Goldstream Gear Pump - Specifications PDF

Download Goldstream Gear Pump - Specifications PDF

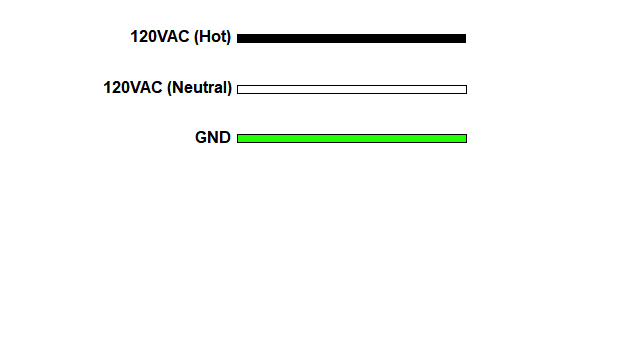

Below, U.S.A. Wiring Colours. NOTE - BLACK is LIVE: