Oilybits OB-3000, Spinning Bowl Centrifuge

Designed for high volume, centrifugal separation of thin liquids, this portable or fixed machine can run 24/7 exerting 1282G on the liquids passing through it, rapidly separating solids, which build up against the inner wall of the centrifuge bowl and can be easily removed periodically.

The centrifuge can be used for any liquids which are not chemically agressive to the machines component materials, these include all petroleum and vegetable derived oils, as well as water based products and blends of water & oil such as cutting fluids. For optimum cleaning performance the liquid should be of a viscosity similar to water, for viscous oils we recommend heating the oil to 30-40c to reduce its viscosity, or pass the oil through the centrifuge at a much slower rate to compensate for the viscosity.

The machine as priced does not include a pump for the incoming contaminated liquid, you could connect your own pump to the machine, alternatively, if you need to buy a suitable pump, please contact us first for advice on which pump to use for the specific liquid you intend to clean. Oilybits can fit a suitable pump to the machine for a nominal charge if required, otherwise the pump can be supplied loose for user assembly.

The machine comes complete with wheels, and levelling feet, so it can be either portable or fixed. For portable 'field' uses, the centrifuge conveniently has a low footprint and can fit into small vans, pick up trucks, or trailers with ease.

Popular Uses:

- Removal of water (when bottom drain ports bolted up), fuel bug, and dirt from Heating Oil or Fuel Oil Tanks (Diesel, Red Diesel, Kerosene, 28Sec Oil Etc Etc)

- Removal of settled fat from biodiesel storage tanks in winter

- Removal of soot and particles from Waste Engine Oil

- Removal of water and food waste from Waste Vegetable Oil

- Removal of glycerol and dirt from Biodiesel

- Removal of metal fragments from Cutting Fluids

- Removal of dirt from Cooling Fluids

- Removal of dirt from water used in a production cycle

These centrifuges are also popular for recovering precious metals in jewellery manufacture, offcuts, swarf, chips, and pastes from polishing can all be recovered or seprated from oils and coolants in a centrifuge, without any valuable metal being trapped in a filter element and lost.

Shown Below: Control Panel

Shown Below: Control Panel Wiring, CE Approved 'Schneider' Electronics throughout

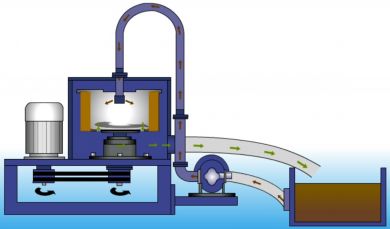

Shown Below: Cutaway diagram showing flow pathway - note, diagram shows a pump (blue article), a pump is not included as the pump will be selected based on your media, but this is where the pump should be sited;

Specification| Voltage | 415v 3-Phase 50Hz, or 230v 1-Phase 50Hz |

| HP | 2 |

| kW | 1.5kW @230v - Start up current in excess of 3000kw, 16A supply required |

| RPM of Centrifuge | 3000 RPM |

| G-Force at Centrifuge Wall | 1282 G |

| Centrifuge Dirt Holding Capacity | 3 Litres |

| Centrifuge Bowl Inner Diameter | 255 mm |

| Optimum Flow Rate for Best Performance | Depends on media type and level of contamination |

| Centrifuge Bowl Dimensions (Internal) | 99 Deep x 255 Dia, 46 Lip (mm) |

| Drain Port Size | 2.5" Hose Barb |

| Machine Dimensions | 970 H x 660 L x 480 W (mm) |

| Weight | 120 kg net |

| Colour | WHITE |

Tariff Code| Description | Code |

| Centrifuge for Liquids | 8421197000 |

Download Oilybits OB-3000 Assembly Diagram 1 PDF

Download Oilybits OB-3000 Assembly Diagram 1 PDF

Download Oilybits OB-3000 Assembly Diagram 2 PDF

Download Oilybits OB-3000 Assembly Diagram 2 PDF

Download Oilybits OB-3000 Drive Mechanism Assembly Diagram PDF

Download Oilybits OB-3000 Drive Mechanism Assembly Diagram PDF