Parker Velcon VF-62 Filter Housing, for Aquacon Filter Cartridges

ALWAYS EMAIL US FOR BEST PRICES ON PARKER VELCON!

The VF-62 is a versatile filter housing designed for use with several different high performance Aquacon filter cartridges, as well as a variety of paper filters and coalescer/ separator cartridges.

Aquacon cartridges filter out water by chemically locking it into layers of super-absorbent media. Water removal efficiency is not affected by common surfactants or additives. Water capacity is as much as 1-1⁄2 quarts, depending on the flow rate. These cartridges also effectively filter out dirt, rust and other particulates.(See caution)

As a cartridge reaches its water- holding limit, the media expands very rapidly and restricts the flow. For oils and other high viscosity liquids, the pressure drop will rapidly increase, signalling the need to change cartridges.

The VF-62, with ACO series cartridges installed, has become the standard for low flow rate full flow aviation fuel monitor applications.

Over Pressure Protection:

When exposed to a high concentration of water, the differential pressure across an Aquacon cartridge will immediately increase. Pressure bypasses or other means to limit the inlet pressure to 75 psi (5 bar) should be installed to prevent the cartridge from collapsing.

Features:

- Aquacon cartridges remove free and emulsified water from fuels to less than 5ppm.

- Filtered water is chemically locked in and can’t be squeezed out.

- Provides Protection against 'slugs' of water.

- Pressure Increase signals cartridge change.

- 0.5 Micron Particle Protection @ 98%+ Efficiency.

Applications:

- Jet Fuel

- Avgas

- Kerosene

- Gasoline

NOTE: For non-EI qualified applications. Housing does not meet EI1596 or EI1581 qualifications.

CAUTION: Do not use Aquacon absorbent cartridges (AC, ACO or AD or ASL Series) with pre- mixed jet fuel containing anti-icing additives, or with gasoline/alcohol blends.

CAUTION: To protect the fuel system, including the filter and other components, be sure to install pressure relief valve(s).

Housing Specification (Supplied Without Cartridge)| Max. Operating Pressure | 150 PSI |

| Material: Head | Cast Aluminium |

| Material: Bowl | Carbon Steel, TGIC-Polyester Coated Interior and Exterior |

| Inlet/Outlet Connection Size | 1,1/2" NPT |

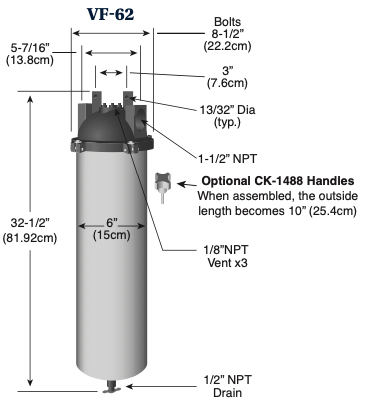

| Distance Between Faces | 5,7/16" (13.8cm) |

| Mounting Holes in Head | |

| O'Ring: For Jet Fuel (Standard) | Buna-N (Spare Part No. G-0986) |

| Height: With Petcock | 32,1/2" (81.92cm) |

| Diameter: Bowl | 6" (15cm) |

| Diameter: Overall | 8,1/2" (22.2cm) |

| Weight: Bare | 16lb |

| Weight: Packaged | 18lb |

| Hardware Included | Buna-N O'Ring, 1/8" Brass Petcock Vent Valve, and 1/2" NPT Drain Valve |

Optional Extras| O'Ring: VITON - For Gasoline / Solvent | Part No. G-0986A |

| Differential Pressure Gauge Assembly | Part No. 10678 |

| Quick Release Hand Bolts (4) | Part No. CK-1488 |

| Drain Valve, Carbon Steel 1⁄2” NPT Ball Valve, with Mounting nipple. | Part No. 554Y020 |

Cartridge Selection Table| Model Number | Type | Media | Application | Micron Rating | Collapse Pressure (PSI) | Flow Rate (US GPM) | Max. Op. Temp. | Data Sheet |

| ACO-52401R | Aquacon | Jet Fuel & Avgas | Dirt & Free Water | 0.5 @ Nom. @ 98% Efficiency | 75 | 10-100 | 250°F / 121.1°C | 1681 |

| AC-52405 | Aquacon | Gasoline | Dirt & Free Water | 5 | | 10-100 | | 1582 |

| AD-52425 | Aquacon | Diesel & Biodiesel | Dirt & Free Water | 25 | | 30-100 | | 1655 |

| AC-52405 | Aquacon | Oils | Dirt & Free Water | 5 | | Varies with oil viscosity | | 1582 |

| AD-52425 | Aquacon | Oils | Dirt & Free Water | 25 | | Varies with oil viscosity | | 1655 |

| ASL-52401 | Aquacon | Solvents | Dirt & Free Water | 1 | | 10-100 | | 1692 |

| FO-524PL1/2 | Paper Filter | All Fuels | Dirt | 0.5 | | 2-100 | | 1549 |

| FO-524PL05 | Paper Filter | All Fuels | Dirt | 5 | | 2-100 | | 1549 |

| FO-524PL25 | Paper Filter | All Fuels | Dirt | 25 | | 2-100 | | 1549 |

Optional Differential Pressure Gauge Assembly, Part No. 10678 For use with VF-62

This unit measures pressure difference between two points. The gauge allows for a simple reading on an easy-to-read scale. A red/green dial with a breakpoint located at 15 psid alerts the user of the condition of the process.

This kit consists of the following components:

- Differential Pressure Gauge: aluminum body, 1/8 ̋ NPT bottom, 1 ̋ molded lens & 0-20 psid scale

- Compression Fittings: 4 straight, 2 90° elbow

- 1/4 O.D. Copper Tubing

Operation:

When the needle is in the green zone of the gauge during normal flow, the differential pressure is less than 15 psid across the installed element, and the element does not need to be changed out.

When the needle is in the red zone, the differential pressure is more than 15 psid and the element should be changed out. It has reached its recommended maximum pressure differential.

Caution:

Do not mount the P/N 10678 differential pressure gauge assembly any closer than 2” from a steel bracket or pipe. The gauge has a magnetic piston, and mounting too close to steel may affect the accuracy.

Download Parker Velcon Aviation Vessels And Housings - Brochure PDF

Download Parker Velcon Aviation Vessels And Housings - Brochure PDF

Download Parker Velcon Filter Housing VF-62 - Brochure PDF

Download Parker Velcon Filter Housing VF-62 - Brochure PDF

Download Parker Velcon Filter Housing VF-62 - Installation Instructions PDF

Download Parker Velcon Filter Housing VF-62 - Installation Instructions PDF