US Filtermaxx, 2400G, 3000G, and 10000G Spinning Bowl Centrifuges

The US Filtermaxx Centrifuge is an american designed & manufactured, high quaity, high precision, high speed spinning-bowl centrifuge, for general centrifugal separation of liquids which are not agressive to the machines component materials.

The US Filtermaxx Centrifuge has been independently assessed and has been found to remove over 98% of particles from 4-38 Microns, and 100% of particles over 70 Microns (At full speed, 2400G, with the oil at 71°c). The laboratory report can be found in the PDF downloads below.

Unlike the Oilybits OB Series Centrifuge, the US Filtermaxx Centrifuge does not use any of the incoming oil for essential lubrication, and therefore everything that passes through the centrifuge had been 'cleaned' to some extent, the slower the centrifuge is fed, the greater the extent of cleaning.

The US Filtermaxx Centrifuge does not use filters, no waste media is created in using the machine, it also does not utilize a pump, and therefore the oil that goes in can be contaminated to a greater extent than oil which needs to pass through a pump into a filtering device.

These centrifuges are also popular for recovering precious metals in jewellery manufacture, offcuts, swarf, chips, and pastes from polishing can all be recovered or seprated from oils and coolants in a centrifuge, without any valuable metal / material being trapped in a filter element and lost.

US Filtermaxx Centrifuge Standard Features:

- High efficiency; 100% reduction of particles >70 Microns, 98%+ reduction of particles >4-38 Microns.

- Fixed Speed, 2400G > USFiltermaxx or Leeson 120 / 240V single-phase 3/4hp, or Baldor 230V/460V 3-phase 3/4hp, pre-wired motors available.

- Fixed Speed, 3000G > USFiltermaxx 240V single-phase 1.5hp motor.

- Fixed Speed, 10000G > USFiltermaxx 230V single-phase or 3-phase 2hp motor.

- Belt overdrive system drives the high-speed rotor while the motor runs at 1800 rpm for a quieter, cooler running, longer lasting centrifuge.

- Large 3.785 Litre displacement bowl that filters 1260 to 3785 Litres of oil per day (Max. rate example; Diesel Polishing @ 20c)

- Clean oil and dirty oil are separated by an internal dam.

- Feed plate distributes oil evenly around circumference.

- Footprint fits on top of 205 Litre Steel Drum.

- Forced Ventilation exhausts vapors released during processing waste oils or biodiesel. Prevents contamination of clean oil by water vapor droplets and ventilates methanol vapors.

- Operating load is taken by 1-inch diameter spindle with replaceable bearings, not the motor bearings as with some other centrifuges.

- Bowl is removed by the quick release spindle in less than a minute.

- Heavy duty 1 inch thick aluminum centrifuge body for rigidity and minimal vibration.

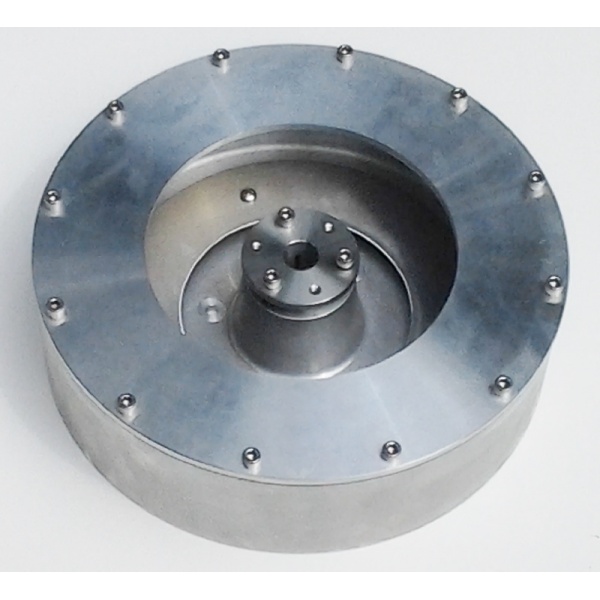

- Rotor is a machined aircraft-grade aluminum casting.

- 15 minutes from box to operation.

- Anti-Vibration Mounting Feet (3)

- Can be switched on/off simply at the power supply, and thus controlled with a timer switch on that supply if desired.

Optional Accessories:

- Automatic Centrifuge Controllers > Allow unit to cycle and drain sludge for unattended cleaning of up to 3785 Litres of oil per day (Example; Diesel Polishing @ 20c)

- Bolt-On Heater Tube/s > Multiples of which can be bolted to the legs of the centrifuge so the unit remains compact and standalone.

US Filtermaxx 1.5kW Heater Specification:

- Long folded element delivers gentle heat so that it does not burn your oil, yet gets hot enough to remove dissolved water and split emulsions.

- Use as standalone, or combine with a US Filtermaxx digital process heater or automatic centrifuge controller.

- Readily mounts to the leg of a US Filtermaxx centrifuge, multiple heaters can be used for high speed heating.

- The slower the flow rate, the hotter the element will heat the oil.

- Adjustable output when combined with Variable Heat Controller.

- Lifetime warranty element - rated to withstand dry firing.

USFiltermaxx 120v 1500w Heater Specification| Power, Fixed (No Power Controller) | 1500w |

| Power, Range (With Variabe Heat Controller) | 1200 to 2500 watts |

| Voltage | 120vAC each, or 230vAC with 2 elements in series |

| Heating Capability | One Element 21c at 55 lph, Two elements in series 42c at 55 lph |

| Length | 20" |

| Watts Density | 24w/in |

| Port Size, Inlet | 1/2" NPT Female |

| Port Size, Outlet | 1/2" NPT Female |

| Port Size, Temperature Probe | 1/4" NPT Female |

USFiltermaxx 2400G Centrifuge Specification| Flow Rate | Dependent on Media & Temperature, Examples: Diesel@20c, 150 LPH, WMO@ 70c 30-40LPH, or WMO@70-95c 30-60 LPH |

| Motor Voltage Range 2400G | 120v1ph30-100Hz, 108-250v1ph30-100Hz, 108-250v3ph30-100Hz |

| Motor Voltage Range 3000G | 208-240v1ph30-100Hz, 208-230v3ph30-100Hz |

| Motor Voltage Range 10000G | 230v1ph50hz |

| Motor RPM | 1800 |

| Centrifuge Bowl RPM | Approximately 5500 |

| Centrifuge Bowl Inside Diameter | Approximately 25.40 cm |

| Centrifuge Bowl Inside Height | Approximately 15.25 cm |

| G-Force at Cleaner Wall | 2400G, 3000G, or 10000G |

| Centrifuge Bowl Dirt Holding Capaciy | Approximately 2.7 Litres |

| Overall Width | 56 cm (fits inside the top lip of a 205 L / 40 Gal Steel Drum) |

| Overall Depth | 56 cm (fits inside the top lip of a 205 L / 40 Gal Steel Drum) |

| Overall Height | 61 cm (allow 30cm above for opening the lid) |

| Weight | <58 Kg |

| Inlet Connection (Liquid) | 1/4" NPT Female |

| Inlet Connection (Ventilating Air) | 1/4" NPT Female |

| Outlet Connection (Clean) | 1,1/4" NPT Female |

| Outlet Connection (Sludge) | 3/4" NPT Female |

| Suitable for | Water, Diesel, WVO, Motor Oil, Biodiesel, ATF, Gear Oil Etc |

| Max Temp | 400 Farenheit |

System Options, Power Requirements| 2400G Centrifuge Only | Start: 20A at 120v or 10A at 240v

Run: 7A at 120v or 3A 1t 240v Approx. |

| 3000G Centrifuge Only | Start: 20A at 240v

Run: 7A at 240v Approx |

| 10000 Centrifuge Only | TBC |

| Heater (Each) Standalone | 15A at 120v and 7.5A at 240v |

| Heater (Each) With Variable Wattage Controller (up to 160v) | 20A at 240v |

Shown Below: Centrifuge Bowl:

Shown Below: Optional 1.5kW Heating Element/s, and 2x elements fitted to centrifuge legs - aids separation by making oil less viscous:

Shown below, Optional P-Trap assembly, to prevent vapour condensate from exiting clean oil line (must never be fitted to sludge line):

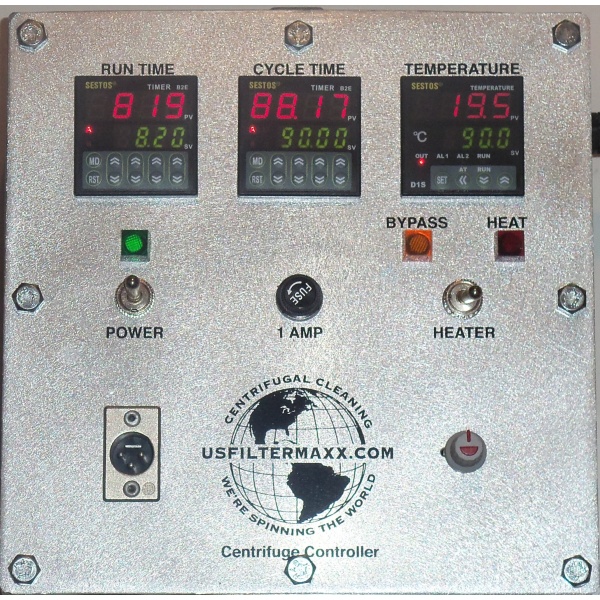

Shown Below; Optional Deluxe Programmable Controller:

- The Deluxe Programmable Controller (Featuring Run Time, Cycle Time, and Temperature Control) allows the centrifuge to clean oil, dump water and sludge and shut down at a preset time for hands-off cleaning with large amounts of oil. Great for WVO, lube oil, used oil, motor oil, hydraulic fluid and diesel fuel polishing. It can control power on/off to 1 or 2 Bolt-On Heaters, if the system is 120V then it can control 1 Heater, if the system is 240v then it can control 2 Heaters. Order the 1 or 2 heaters, plus the flow control valve, separately from the options.

Shown Below; Optional Deluxe Variable Heater Wattage Programmable Controller:

- With all the features of the Deluxe Programmable Controller, plus variable wattage heater control, so you can change the heating power from 1250 watts to 2400 watts by turning a knob. Also featuring a Flow Sensor to shut down the heaters should the oil stop flowing. Order the 1 or 2 heaters, plus the flow control valve, separately from the options.

Shown Below; Optional Economy Programmable Cycle-Time Controller:

- The Economy Programmable Cycle-Time Controller allows the centrifuge to clean oil, dump water and sludge and shut down between cycles for hands-off cleaning with large amounts of oil.

Shown Below; Optional Economy Programmable Temperature Controller:

- The Economy Programmable Temperature Controller, switches the heating element/s on/off as the line temperature reaches pre-set thresholds.

Shown Below; Optional Motorized Ball Valve for use with Deluxe Controller with Temperature Control:

Shown Below; Videos on Programmable Controllers and Ball Valve Wiring:

Shown Below; Video showing inside the unit, and the sludge separation system:

Shown Below; Video showing the build-up of sludge in a typical waste motor-oil cleaning scenario:

Tariff Code| Description | Code |

| Centrifuge for Liquids | 8421197000 |

Download USFiltermaxx - Venting Vapours & P-Trap Installation PDF

Download USFiltermaxx - Venting Vapours & P-Trap Installation PDF

Download USFiltermaxx - Lab test report of WMO sample run at 160F, at 40 lph PDF

Download USFiltermaxx - Lab test report of WMO sample run at 160F, at 40 lph PDF