Zuwa Zumpe, Flexible Impeller Pumps, Motor Driven (Stainless Steel), ATEX Approved

2021 - Zuwa have imposed a Minimum Order Value, so we are now unable to supply Zuwa products below the combined value of, currently, 650.00 GBP.

With Cat 2 ATEX Approved motor, for use in Zone 1 Explosive Atmospheres. Please note it is only the motor which is ATEX approved, not the pump itself, therefore they should only be used for pumping of liquids with a flashpoint of 55°+

Featuring a Stainless Steel impeller case, and Stainless Steel end closure, these pumps are designed for liquids which are not chemically agressive to Stainless Steel, and are mildly abrasive, the Stainless Steel impeller case preventing wear of the impeller chamber.

VERSIONS WITH EPDM OR NEOPRENE IMPELLERS ARE ALSO SUITABLE FOR FOODSTUFFS AND F.D.A. COMPLIANT CERTIFICATES ARE PROVIDED WITH THIS MODEL.

These top quality, extremely durable Flexible-Impeller pumps are excellent for pumping viscous liquids which have a particulate content, for example Waste Engine Oil, Waste Cutting Oil, Waste Lubricating Oil, Waste Vegetable Oil, and Waste Glycerine (Subject to selection of the correct impellor material for chemical compatibility). The motors supplied with these pumps are Continuous Duty rated, and will go on and on

The Flexible Impeller itself is made from either NBR, Viton, Neoprene, or EPDM, Viton being a rubber which is chemically resistant to liquids of many types including the above mentioned liquids. The impeller blades flex as particle matter passes between them and the pump housing, this prevents damage to the impeller and promotes long life of the pump. NBR is suitable for conventional diesel and motor oils only

These pumps are especially popular with producers of Bio Fuels, who require pumps which can suck up Waste Oil from a storage bin / tank and dispense it into a drum or other vessel for removal from site

Available in 230vAC 50Hz only

ATEX Motor Specification; II 2G Exd IIC T4 GB IP66 Ta-20/+50°C

Female Threaded Hose Tails can be found at the links below;

Not all options are listed - for further information or assistance in selecting the right pump, please email us or give us a call!

Impeller Maximum Operating Temperatures| Material | Maximum Operating Temperature |

| NBR | 90°c |

| EPDM | 90°c |

| Viton | 90°c |

| Neoprene | 90°c |

| Desmopan (TPU) | 60°c |

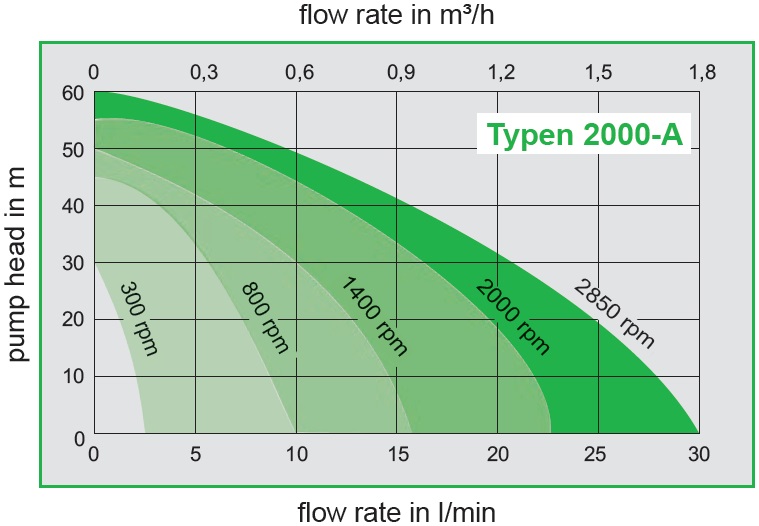

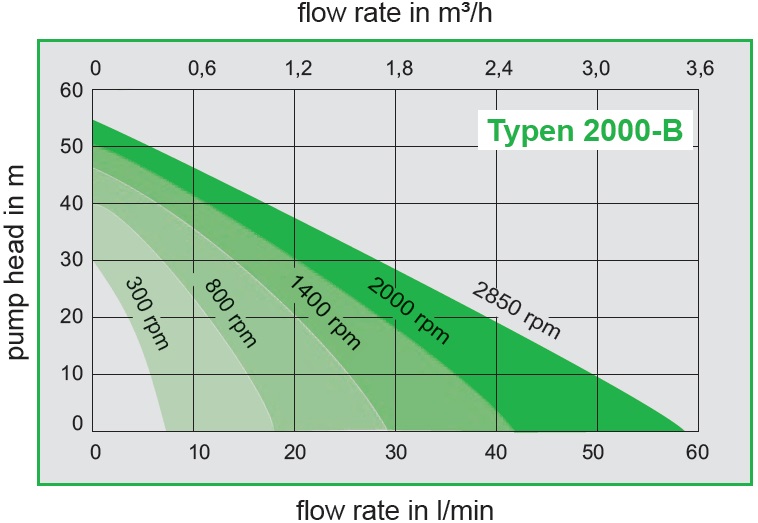

Performance| Model | 2000-A | 2000-B |

| Flow Rate | 30 lpm @ 2900 RPM | 60 lpm @ 2900 RPM |

| Suction Head Max (Dry) Using NBR Impellor | 3m | 3m |

| Suction Head Max (Wet) Using NBR Impellor | 7m | 7m |

| Outlet Pressure Max @ 2860 RPM | 5 Bar | 5 Bar |

| Liquid Temperature Max | Dependent on Impeller Selection | Dependent on Impeller Selection |

| Inlet Fitting | 3/4" BSP Male | 1" BSP Male |

| Outlet Fitting | 3/4" BSP Male | 1" BSP Male |

Motor Specifications| Voltage | RPM | 2000-A kW | 2000-B Kw | IP Rating | ATEX Rating |

| 230vAC | 2860 | 0.37 | 0.55 | IP 66 | II2G Exd IIC T4 Ta-20/+50°c |

Wetted Components| Housing | Stainless Steel; 1.4571 |

| Cover | Stainless Steel; 1.4571 |

| Shaft | Stainless Steel; 1.4104 |

| Impeller | NBR, Viton, Neoprene or EPDM |

| Shaft Seal | NBR, Viton, Neoprene or EPDM |

| Impeller Case & Cover Seal | NBR, Viton, Neoprene or EPDM |

Shown Below; Optional Pump Carrier;

A pump carrier serves to protect the motor from ingress of liquids that may be corrosive to the pump shaft seal, if the seal is compromised, the liquid will leak out of the pump, and out through the carrier into a drip tray / absorption mat, instead of entering the motor winding's, destroying the motor.

*PUMP CARRIER MUST BE ORDERED WITH THE PUMP/S, IT CANNOT BE FITTED IN RETROSPECT*

Performance Curve - 2000-A

Performance Curve - 2000-B

Download ATEX Certificate PDF

Download ATEX Certificate PDF