Elaflex 'Yellow-Band' Statically Bonded (ATEX), Cloth Reinforced Aviation Fuel Hose

'Yellow Band' Aircraft Refuelling Hoses, suitable for all aviaition gasolines and jet fuels (Jet A-1), de-icing fluids, and motor oils. This hose is statically bonded, for use in an ATEX Zone

Applicable Standards to which all 4 hoses meet:

- EN ISO 1825 (EN 1361)

- EN 12115 NBR 1 (Rubber and thermoplastics hoses and hose assemblies for liquid or gaseous chemicals)

- EN 1761 (Rubber hoses and hose assemblies for fuel truck delivery)

- American Standard EI 1529 (Equivalent to EN ISO 1825)

- NFPA 407

- AS 2683

- German Military Standard VG 95 955

- By grounding the embedded wire the hose is electrically bonded. The electrical resistance R ≤ 10㎡ Ohm/m is according to ISO 8031 - ATEX Directive 94/4/EC and 99/92/EC).

Information printed along hose, Date of Manufacture, Batch No.,

There are 4 variants of the Yellow-Band hose, for different applications around the airfield;

| Option | Characteristics | Uses |

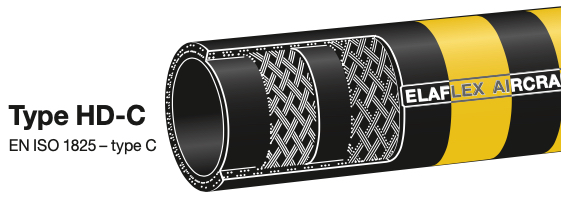

| HD-C | Flexible | Hydrant inlet (use spiral form neon markings) and into-plane use. |

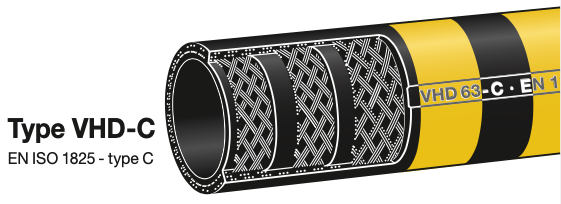

| VHD-C | Fortified | Reel-into-plane and hydrant inlet (use spiral form neon markings), as well as riser systems. |

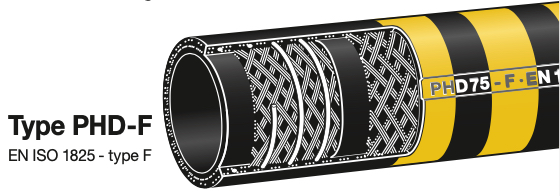

| PHD-F | Thick Wall | Alternative fuelling and de-fuelling use. |

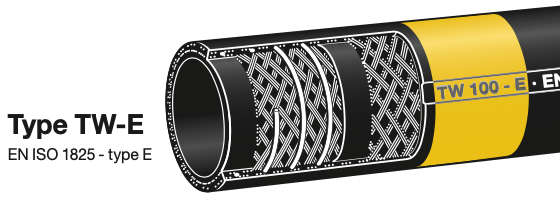

| TW-E | Hard Wall | Tank truck, and the connection between truck and trailer, as well as riser systems (Not for hydrant inlet or into-plane fuelling). |

| LT | Low Temperature Type | For use in particularly cold areas, all aircraft refuelling hoses can be produced in a special soft and cold flexible 'LT' version ( LOW TEMPERATURE ). This hose may be used without risk of cracking at temperatures down to – 50° Celsius. Because of the softer tube the max. vacuum resistance of type HD-LT and VHD-LT is slightly lower, and the extraction and swelling of the tube slightly increases. LT Hose is not manufactured in neon. |

Hose can be supplied in cut lengths or with male threaded ends, three types of end connection are available:

Yellow-Band General Specifications| Material - Lining | Nitrile Rubber (NBR), Impermeable to Fuels. |

| Material - Cover | Chloroprene (CR), Flame & Abrasion Resistant. |

| Reinforcement | HD-C = 2 Textile braids without metallic strands

VHD-C = 3 Textile braids without metallic strands

PHD-F = 2 Textile braids without metallic strands and non-metallic plastic helix

TW-E = 2 Textile braids without metallic strands and galvanised steel helix |

| Inner Colour | Black |

| Outer Colour | Black with 2 Yellow Bands every 4m |

| Working Pressure | 20 Bar |

| Test Pressure | 40 Bar |

| Temperature Range | HD-C, VHD-C, PHD-F, TW-E = -30 to +90 Celcius (LT Versions of same to -50 Celcius) |

| Antistatic | Yes |

| Ageing and Ozone Resistant Outer | Yes |

HD-C Specifications| Hose I.D. (Inches) | Hose I.D. (mm) | Hose O.D. (mm) | Reel Diameter (min) (2x Bend Radius) | Pressure (Working) | Pressure (Maximum) | Vacuum (Maximum) | Weight (kg/m) | Coil Length (m) | Part Number |

| 3/8 | 10 | 19 | 140 mm | 20 Bar | 40 Bar | -0.8 Bar | 0.3 | | HD 10 C |

| 3/4 | 19 | 31 | 200 mm | 20 Bar | 40 Bar | -0.6 Bar | 0.6 | 40 | HD 19 C

HD 19 C NEON |

| 1 | 25 | 37 | 200 mm | 20 Bar | 40 Bar | -0.5 Bar | 0.8 | 30 / 40 / 50 / 60 / 80 | HD 25 C

HD 25 C NEON |

| 1,1/4 | 32 | 44 | 225 mm | 20 Bar | 40 Bar | -0.4 Bar | 1.0 | 30 / 40 / 50 / 60 / 80 | HD 32 C

HD 32 C NEON |

| 1,1/2 | 38 | 51 | 270 mm | 20 Bar | 40 Bar | -0.3 Bar | 1.2 | 30 / 40 / 50 / 60 / 80 | HD 38 C

HD 38 C NEON |

| 2 | 50 | 66 | 400 mm | 20 Bar | 40 Bar | -0.3 Bar | 1.9 | 30 / 40 / 50 / 60 / 80 | HD 50 C

HD 50 C NEON |

| 2,1/2 | 63 | 79 | 600 mm | 20 Bar | 40 Bar | -0.2 Bar | 2.4 | 30 / 40 | HD 63 C

HD 63 C NEON |

| 3 | 75 | 91 | 600 mm | 20 Bar | 40 Bar | None | 2.8 | 40 | HD 75 C

HD 75 C NEON |

| 4 | 100 | 116 | 900 mm | 20 Bar | 40 Bar | None | 3.7 | 40 | HD 100 C

HD 100 C NEON |

VHD-C Specifications| Hose I.D. (Inches) | Hose I.D. (mm) | Hose O.D. (mm) | Reel Diameter (min) (2x Bend Radius) | Pressure (Working) | Pressure (Maximum) | Vacuum (Maximum) | Weight (kg/m) | Coil Length (m) | Part Number |

| 1,1/2 | 38 | 52 | 400 mm | 20 Bar | 40 Bar | -0.6 Bar | 1.2 | 40 | VHD 38 C

VHD 38 C NEON |

| 2 | 50 | 67 | 500 mm | 20 Bar | 40 Bar | -0.5 Bar | 2.0 | 25 / 30 / 40 | VHD 50 C

VHD 50 C NEON |

| 2,1/2 | 63 | 81 | 550 mm | 20 Bar | 40 Bar | -0.4 Bar | 2.8 | 25 / 30 / 40 | VHD 63 C

VHD 63 C NEON |

| 3 | 75 | 93 | 600 mm | 20 Bar | 40 Bar | -0.2 Bar | 3.4 | 40 | VHD 75 C

VHD 75 C NEON |

| 4 | 100 | 118 | Not Suitable | 20 Bar | 40 Bar | None | 4.4 | 35 / 40 | VHD 100 C

VHD 100 C NEON |

PHD-F Specifications| Hose I.D. (Inches) | Hose I.D. (mm) | Hose O.D. (mm) | Reel Diameter (min) (2x Bend Radius) | Pressure (Working) | Pressure (Maximum) | Vacuum (Maximum) | Weight (kg/m) | Coil Length (m) | Part Number |

| 1,1/2 | 38 | 54 | 400 mm | 20 Bar | 40 Bar | -0.8 Bar | 1.5 | 25 / 30 / 40 | PHD-F 38 C

PHD-F 38 C NEON |

| 2 | 50 | 67 | 500 mm | 20 Bar | 40 Bar | -0.8 Bar | 2.1 | 25 / 30 / 40 | PHD-F 50 C

PHD-F 50 C NEON |

| 2,1/2 | 63 | 81 | 550 mm | 20 Bar | 40 Bar | -0.7 Bar | 2.9 | 25 / 30 / 40 | PHD-F 63 C

PHD-F 63 C NEON |

| 3 | 75 | 93 | 600 mm | 20 Bar | 40 Bar | -0.6 Bar | 3.6 | 40 | PHD-F 75 C

PHD-F 75 C NEON |

TW-E Specifications| Hose I.D. (Inches) | Hose I.D. (mm) | Hose O.D. (mm) | Reel Diameter (min) (2x Bend Radius) | Pressure (Working) | Pressure (Maximum) | Vacuum (Maximum) | Weight (kg/m) | Coil Length (m) | Part Number |

| 1 | 25 | 37 | 200 mm | 20 Bar | 40 Bar | -0.8 Bar | 0.8 | 40 | TW 25 E |

| 1,1/4 | 32 | 44 | 225 mm | 20 Bar | 40 Bar | -0.8 Bar | 1.0 | 40 | TW 32 E |

| 1,1/2 | 38 | 51 | 400 mm | 20 Bar | 40 Bar | -0.8 Bar | 1.4 | 40 | TW 38 E |

| 2 | 50 | 66 | 500 mm | 20 Bar | 40 Bar | -0.8 Bar | 2.1 | 40 | TW 50 E |

| 2,1/2 | 63 | 79 | 550 mm | 20 Bar | 40 Bar | -0.8 Bar | 2.8 | 40 | TW 63 E |

| 3 | 75 | 91 | 600 mm | 20 Bar | 40 Bar | -0.8 Bar | 3.3 | 40 | TW 75 E |

| 4 | 100 | 117 | 900 mm | 20 Bar | 40 Bar | -0.8 Bar | 4.7 | 40 | TW 100 E |

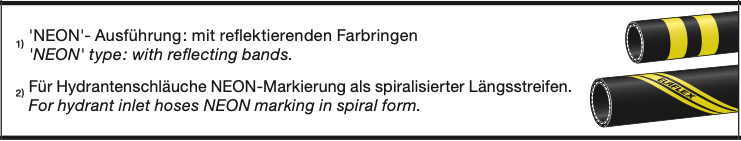

Below: Neon Markings, use spiral form for hydrant inlet hoses.

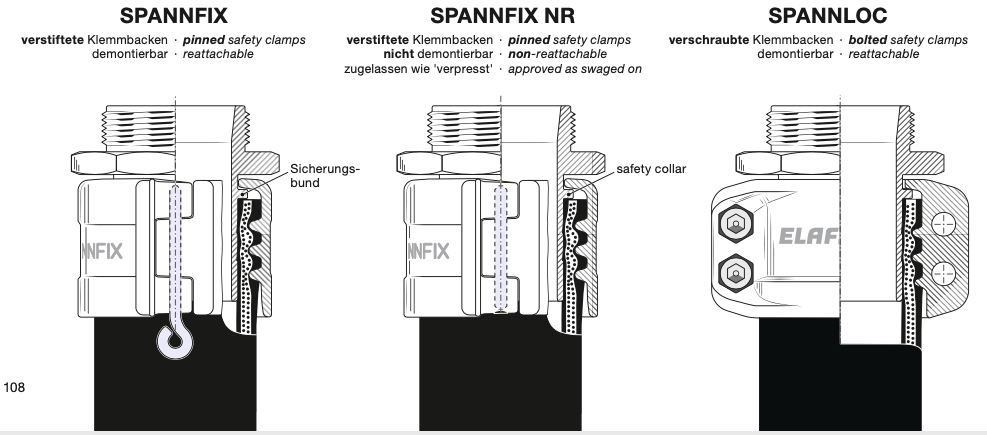

Below: Fittings available for hose ends.

Download Elaflex Yellow-Band Aviation Fuel Hose - Brochure PDF

Download Elaflex Yellow-Band Aviation Fuel Hose - Brochure PDF

Download Elaflex End Fittings, Threaded, with Spannloc Clamps - Brochure PDF

Download Elaflex End Fittings, Threaded, with Spannloc Clamps - Brochure PDF

Download Elaflex End Fittings, Threaded, with Spannfix Clamps - Brochure PDF

Download Elaflex End Fittings, Threaded, with Spannfix Clamps - Brochure PDF

Download Elaflex End Fittings, Flanged DN19-DN63 - Brochure PDF

Download Elaflex End Fittings, Flanged DN19-DN63 - Brochure PDF

Download Elaflex End Fittings, Flanged DN75-DN200 - Brochure PDF

Download Elaflex End Fittings, Flanged DN75-DN200 - Brochure PDF

Download Elaflex Hose, Certificate of Conformity - EXAMPLE PDF

Download Elaflex Hose, Certificate of Conformity - EXAMPLE PDF