Shell Water Detector Capsules for Jet Fuels, Box of 80 Capsules

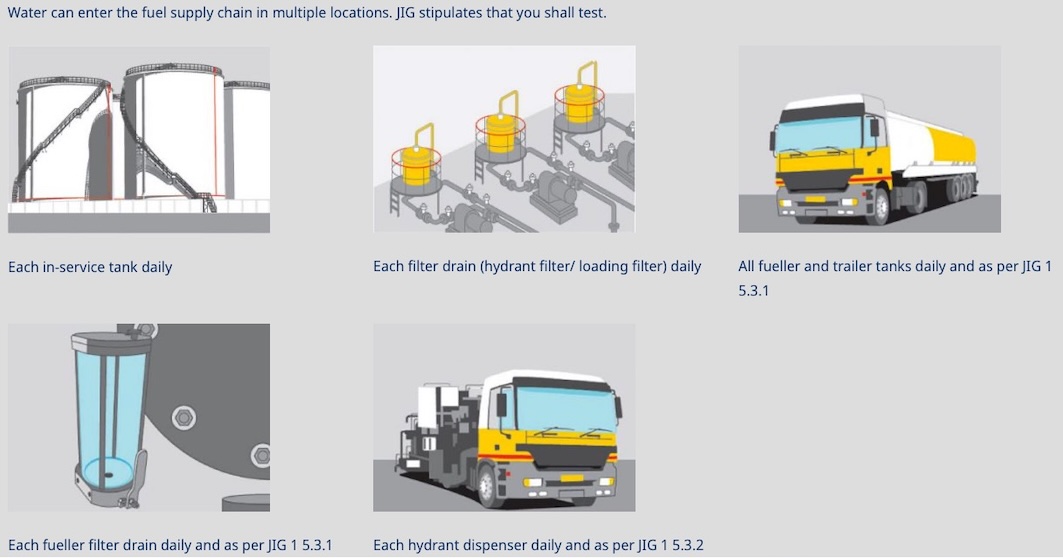

The aviation industry's test system of choice, employed over 8 million times a year around the world. Using a syringe fitted with a Shell Water Detector capsule, it only takes a matter of moments to check the fuel at any stage of your delivery system. And these capsules are probably the most cost-effective safety measure you'll ever introduce.

Screw-top tubes can be difficult to use, especially when wearing gloves. Shell understand the importance of sampling efficiently while wearing the correct personal protective equipment, which is why the new Shell Water Detector tubes have flip caps. These are easy to open and seal with one hand while wearing gloves. We also recommend using reverse-action syringes, which draw samples in when the plunger is pushed – an action that can be performed easily using one hand.

Enhanced product quality assurance

- The Shell Water Detector kits continue to be manufactured to high quality standards.

- The new desiccant-coated tubes are medical-grade quality, which helps to ensure that the capsules remain protected during the rigors of use.

- The new tubes help to ensure that the remaining capsules are protected from moisture, through simple flip tops, which are easier to seal from the air, and an all-over desiccant coating, which has replaced the desiccant sachet placed at one end of the tube. This improves the protection of the capsules against ambient moisture, especially in humid locations.

Supplied in boxes, each box containing 8 tubes of 10 capsules per tube (total 80 capsules)

The capsules are used to determine the presence of finely dispersed undissolved water in jet fuel at concentrations lower than normally detectable by visual examination.

1 Box of 80 Capsules is 110 x 90 x 45 mm, 225 g

1 Outer box of 50 Boxes (of 80 Capsules) is 245 x 235 x 470 mm, 11.55 Kg

LIFESPAN:

- Shell Water Detector Capsules have a lifespan of 9 months from date of manufacture.

- Once manufactured they are independently tested, reducing this by up to 1 month by the time distributors recieve them.

- The lifespan when they leave Oilybits Ltd will therefore be between 7-8 Months.

Water Sensitivity| Fuel | Point at which water droplets are visible |

| Jet Fuel | At 15 ppm the centre is greenish yellow; at around 30 ppm it is a distinct green. Note that different dispersed water limits (30 ppm or 15 ppm) can apply depending on the QA standards in place, see IATA guidance material or ATA 103 for details |

Notes from Shell regarding application:

- - - Quote - - -

The Shell Water detector is a robust, easy to use and cost-effective field test designed to be a go / no-go indication of 30ppm of water in jet fuel. To achieve this, the indicator paper changes from yellow to a blue colour when drawing a 5ml sample (obviously the sensitivity can be varied by drawing different quantities of water).

The Shell Water Detector is not designed to be a quantitative test; however, you can perhaps imagine that there is a progressive change in colour with increasing levels of water and the colour change is not purely binary. As a result, the capsule is designed to achieve a strong identifiable colour at 30ppm, leaving a residual risk that some operators may identify a colour change at lower water quantities (so failing in the safe direction). However, if we consider how this equipment is used, which is primarily at into-wing applications, then the water level at this point is typically low single digit ppm levels and so below the lower indication limits of the capsules. I mention this as it effectively eliminates false positives in a well-run fuel supply system and while levels between 10 and 30ppm may be noticed by an operator should they be present and could be perceived as a false positive, they also effectively give early warning of some upstream process or fuel management upset that really should be investigated.

- - - Un-Quote - - -

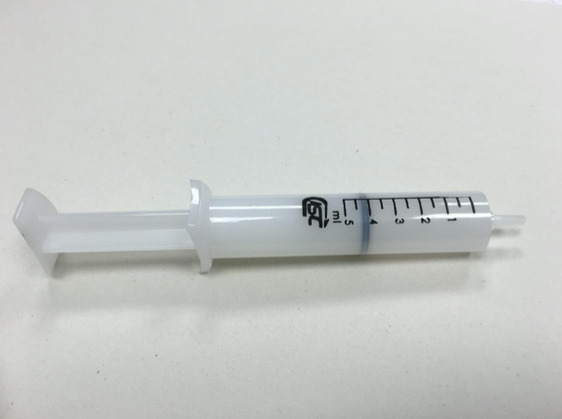

Available seperately are Reverse-Action, and Standard-Action Syringes. The Reverse-Action Syringe enables single-handed operation, the syringe is used to extract a fuel sample from any part of the fuel system, and then the sample is injected into the Shell Water Detector Capsule.

Shown Below - ASC (formerly branded 'SESI') Standard Action Syringe:

Shown Below - ASC Reverse Action Syringe & Components:

Other Syringes for Shell Water Detector:

Commodity Codes| Water Indicating Capsules / Strips | 9026808000 |

| Syringes (Fuel Samplers) | 90269010 |

Download Shell Water Detector - Brochure PDF

Download Shell Water Detector - Brochure PDF

Download Shell Water Detector - MSDS PDF

Download Shell Water Detector - MSDS PDF

Download Shell Water Detector - Packaged Instructions PDF

Download Shell Water Detector - Packaged Instructions PDF

Download Shell Water Detector - Written Instructions PDF

Download Shell Water Detector - Written Instructions PDF

Download Shell Water Detector - Example Certificate Of Origin PDF

Download Shell Water Detector - Example Certificate Of Origin PDF

Download Shell Water Detector Syringe - Operating Manual PDF

Download Shell Water Detector Syringe - Operating Manual PDF