Static Grounding Reel, Stainless Steel, ATEX Approved

- ATEX certified.

- Conforms to API RP 2219, Max 1MΩ when maintained according to the manual.

- Conforms to JIG standards, Max 25Ω / 0.000025MΩ between bracket & clip

- 304 Stainless Steel Construction, with PVC hub and Graphite Contact Bush.

- 5.5mmOD PVC Coated, Braided Copper Cable, 15m or 40m standard capacities (custom lengths available upon request). Arctic Grade Cable also available.

- Adjustable brake, to eliminate over-run.

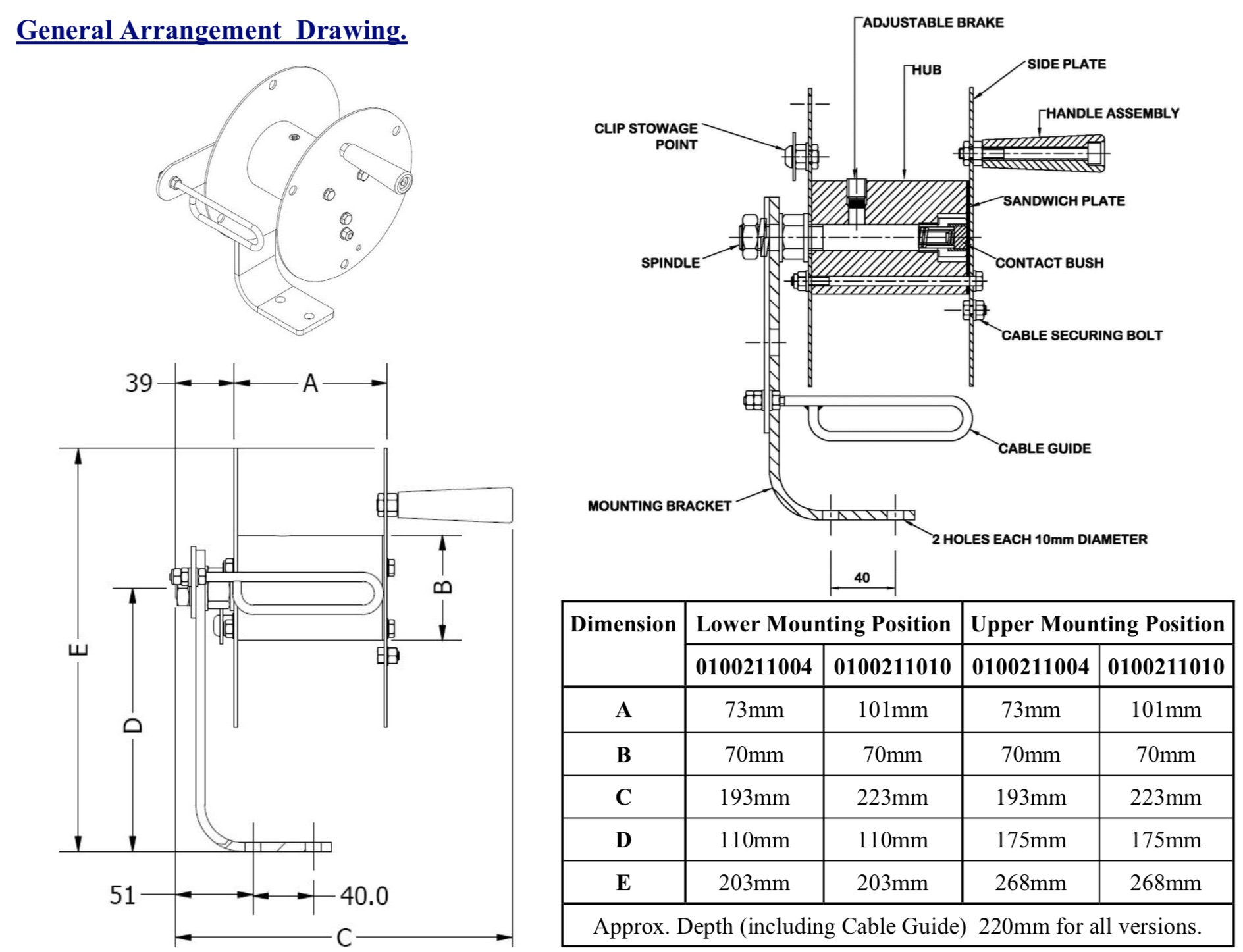

- Optional Cable Guide Bracket Assembly. (Shown in main image, but not included as standard)

- Optional Break-Away Joint - for use with Helicopters. (Shown below)

- 170mm Superclip with Red Handles as standard, other clamps available.

Shown Below: Break-Away Joint

Introduction

When transferring flammable liquids or powders at high flow rates it is essential that adjacent system components are electrically connected, or bonded, in order to reduce the risk from potentially explosive static electrical discharges. Traditionally this connection has been achieved using a bonding clip and cable stowed on an electrically conductive reel.

History

In the past Bonding Reels were made from thick Aluminium or Brass castings, so in the event of failure or damage occurring it meant replacing a large expensive component. They relied on the hub bearing to provide the electrical circuit through the reel, but when the bearing became worn this resulted in a loss of continuity. The reeling resistance was low so during unreeling the reel continued to spin in an uncontrolled manner and deposited cable on the ground.

The Cable Reel has been specifically developed to overcome these shortcomings.

Description

The Cable Reel offers an extended operational life and it can be fully overhauled very simply. Our reel does not rely on contact between the hub and spindle for its electrical connection, instead it uses an internal spring loaded Graphite contact bush which is connected to the spindle and bears directly on a Brass sandwich plate which is clamped to the side plate. This ensures a clean 100% contact. Because the hub is not required for continuity it is made from rigid PVC which provides a maintenance free bearing. Stainless steel is used for all other major components. A dedicated clip stowage point prevents clip loss and inadvertent unreeling during vehicular movement.

The Cable Reel is available in two sizes, to accommodate up to 15 metres or up to 40 metres of cable. A heavy duty insulated Brass clip is fitted together with the required length of cable. The standard cable is transparent PVC insulated 16x14x0.15 Copper braid. The reel is fitted with an adjustable friction brake to eliminate over-run when unreeling. The reel can also be fitted with an optional adjustable cable guide which allows the cable to be pulled out at an acute angle without it fouling on the side plates.

Cable Specification:

- 16x14x0.15 single Copper braid to 3mm diameter.

- High Visibility Transparent Green PVC to 5.5mm diameter.

- 0.007 Ohms per metre electrical Resistance

- 0.06Kg/Metre Approx.

- - 20°c Min. Temp.

Other Available Options| Description | Part Number | Minimum Cold Flex Temperature |

| Clear PVC Cable | 0100212001 | -20°c |

| High-Visibility Yellow PVC Cable | 0100212005 | -20°c |

| Arctic Grade Cable | 0100212007 | -40°c |

ATEX

The Cable Reel has been risk assessed to comply with the requirements of the below EC directives and harmonised standards, including ATEX Directive 94/9/EC for use in Zone 1 hazardous areas, and it is CE marked:

- 94/9/EC Directive on equipment and protective systems intended for use in potentially explosive atmospheres (ATEX).

- 2006/42/EC Directive on machinery.

- BS EN 13463-1:2009 Non-electrical equipment for use in potentially explosive atmospheres – Part 1: Basic method and requirements.

- BS EN 13463-5:2011 Non-electrical equipment intended for use in potentially explosive atmospheres. Protection by constructional safety ‘c’.

- BS EN 1127-1:2011 Explosive atmospheres. Explosion prevention and protection. Basic concepts and methodology.

The reel is suitable for use in Zone 1 Category 2 (Gas and Dust) hazard areas, when installed, operated and maintained in accordance to the operating manual, and carries the following markings:

CE Ex II 2 G c IIC T6

CE Ex II 2 D c

Models Available| Model Number | Cable Capacity | Weight (bare reel) | Weight (complete with max length of cable) |

| 0100211004 | 15m | 1.9 Kg | 2.8 Kg |

| 0100211010 | 40m | 2.2 Kg | 4.6 Kg |

Commodity Codes| Grounding Reels | 8479899790 |