Oilybits RPC-103 'Raw Power Extreme' Spinning Bowl Centrifuge

PLEASE NOTE - This is a self-assembly kit in component form, the kits are of USA manufacture, and so threads and fixings are imperial, you will need a comprehensive tool kit and basic skills to assemble it, and wire it up safely. Oilybits now include a pack containing some items which will enable completion without having to purchase extra electrical components, the responsibility of safe assembly is that of the purchaser.

The Raw Power Centrifuge is an american designed & manufactured, high quaity, high precision, high speed, spinning-bowl centrifuge, for general centrifugal separation of liquids which are not agressive to the machines component materials.

Unlike Oilybits OB Series Centrifuge, the Raw Power Centrifuge does not use any of the incoming oil for essential lubrication, and therefore everything that passes through the centrifuge had been 'cleaned' to some extent, the slower the centrifuge is fed, the greater the extent of cleaning.

The Raw Power Centrifuge does not use filters, no waste media is created in using the machine, it also does not utilize a pump, and therefore the oil that goes in can be contaminated to a greater extent than oil which needs to pass through a pump. Particle size is limited to approximately 5mm Dia., this is the clearance between the rotor and the performance optimiser through which the dirty oil first flows, without the Performance Optimiser in place, the particle size increases to approximately 15mm Dia., the bore of the inlet hose tail.

The Raw Power Centrifuge is supplied as standard with a 'Performance Optimizer', this increases the efficiency of the centrifuge for ultimate cleaning performance while maintaining the easy and quick cleaning ability of the open bowl design. The optimizer bolts in to the rotor bowl with no modification and does not need to be removed when cleaning the bowl. The optimizer gets the oil spinning at full RPM prior to entering the bowl, rather than hitting the bowl static, this reduces turbulence / imbalance in the bowl. Also, the Performance Optimiser feeds the incoming/dirty oil directly to the outside wall at the bottom of the bowl, forcing the dirty oil to have to work its way from bottom to top, and outside to inside, then over the lip and out of the bowl, maximising its residence time, and therefore the efficiency of the cleaning operation.

The Raw Power Centrifuge has a dedicated drainage port for dirty oil and any liquid sludge, when the bowl stops spinning, the contents flood the base of the bowl and drain out through 3 small ports, into a sump beneath the bowl, and then out through a dedicated fitting below the bowl. Large particles over approximately 4mm will need manually scraping out of the bowl as they are too large to pass through the 3 small drainage ports.

These centrifuges are also popular for recovering precious metals in jewellery manufacture, offcuts, swarf, chips, and pastes from polishing can all be recovered or seprated from oils and coolants in a centrifuge, without any valuable metal being trapped in a filter element and lost.

Centrifuge Specification| Flow Rate | Dependent on Media, Est. Diesel @ 20c, 19-95 LPH |

| Supply Voltage Options | 1) 230v1Ph 50-60Hz, With Phase(speed) Controller included, powering a 3Ph230v60Hz motor

2) 110v1Ph 50-60Hz. With Phase(speed) Controller included, powering a 3Ph230v60Hz motor |

| RPM | 6000 |

| Centrifuge Bowl Inside Diameter | 190.5 mm |

| G-Force at Cleaner Wall | 3824 G |

| Centrifuge Bowl Dirt Holding Capaciy | 0.7 Litres |

| Overall Width | 40 cm |

| Overall Depth | 40 cm |

| Overall Height | 50 cm |

| Weight | 23 Kg |

| Inlet / Outlet / Sludge Connection | 3/4" NPT Female with 3/4" Hose Barbs Supplied |

| Suitable for | Water, Diesel, WVO, Motor Oil, Biodiesel, ATF, Gear Oil Etc |

| Max Temp | 400 Farenheit |

Heating Element Specifications| Voltage | 110v or 230 50/60Hz 1Ph |

| Power | 1000 W |

| Temperature Range | 15 to 120 C |

| Port Size | 3/4"NPT Female (Both In & Out) |

| Hose Barbs (supplied loose) | For 3/4"ID Hose |

| Hose Material (supplied loose) | Silicone |

| Housing Material | Cast Aluminium |

| Element Material | Stainless Steel |

Imperial Tools Required for Assembly| For | Type | Thread Size (For Ref. Only) |

| Motor to Centrifuge Mounting Bolts (4) | 7/32" Hex Key | |

| Motor Electrical Enclosure Cover (4) | 1/4" Hex Socket | |

| Motor Earth Bolt (1) | 5/16" Hex socket | |

| Leg Mounting Bolts (8) | 5/32" Hex Key | |

| Grease Retaining Grub Screws in Shaft Bushing (2) | 3/32" Hex Key | 10-24 UNC |

| Rubber Feet (3) | 1/2" Hex Socket | |

| Performance Optimiser (3) | 3/16" Hex Key | |

Shown Below: Centrifuge with lid off (optimiser not fitted).

Shown Below: Performance Optimiser

Shown Below: Optional Heating Element with Temperature Control Knob 15-120c.

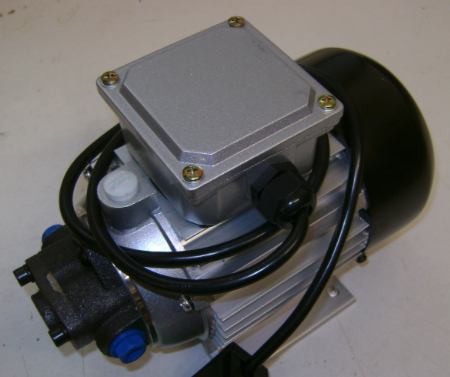

Shown Below: Phase(speed) Controller (Variable Frequency Device)

NOTE: The RPC-103 has been supplied with various VFD's in recent months due to supply shortages, they all perform the same as far as the RPC-103 is concerned, at the bottom of this page are instructions for all 3 types currently in use, we ship whatever comes in with the kits.

- The RPC-103 is supplied as standard with a Phase(speed) Controller, which runs the 230v, 6000 RPM motor on the Raw Power Extreme Centrifuge.

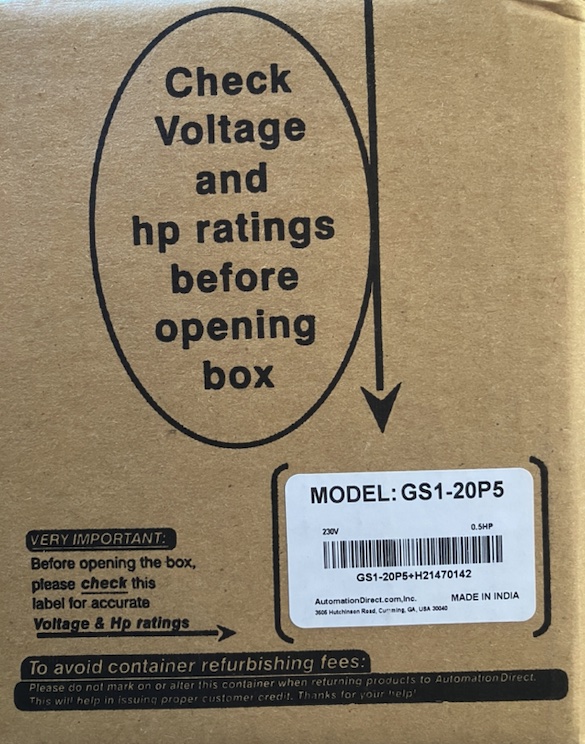

- Images 1 & 2: Automation Direct GS1-20P5 (230v)

- Images 3 & 4: ABB ACS55 & ABB Speed Potentiometer (230v)

- Image 5: Automation Direct GS10 Dura Pulse GS11N-20P5 (230v)

- Automation Direct GS10 Dura Pulse GS11N-11P0 (110v)

Shown Below: Included with the centrifuge and heater are packs of electrical fittings to complete assembly without the need to buy extra components.

- See PDF Downloads below for the datasheets for each pack.

OPTIONAL ACCESSORIES AND PARTS:

Shown Below: Replacement Bowl Kit (Also purchased on its own by some people who want to try making their own centrifuge).

- Single-piece aluminium bowl, machined from bar stock for perfect balance

- Clamp Bushing for 5/8" OD motor shaft (no shaft key)

Shown Below: Low-flow Cast Iron, Miniature Gear Pump for Oils, for feeding the centrifuge at a controlled rate of 30 LPH.

- Single speed, 30 LPH displacement

- Continuous Duty

- 230v50HZ1Ph

- 1/8"BSP Female Ports

- You will need to order appropriate tube and fititngs seperately to complete the assembly.

- Click HERE to take you to the product page

Shipping Information| Description | Packaged Dimensions & Weight | Code |

| Centrifuge Kit | 53 x 43 x 40 cm's, Wt. 25.4 Kg | 8421197000 |

| Centrifuge Kit + Heater | 53 x 43 x 40 cm's, Wt. 26.8 Kg | 8421197000 |

| Heating Element | 15 x 15 x 40 cm's, Wt. 2.5 Kg | 8516108000 |

Download RPC-103 Instruction Manual (Ft. ABB ACS55 VFD), PDF

Download RPC-103 Instruction Manual (Ft. ABB ACS55 VFD), PDF

Download RPC-103 Fittings Kit, PDF

Download RPC-103 Fittings Kit, PDF

Download RPC-103 Heater Fittings Kit, PDF

Download RPC-103 Heater Fittings Kit, PDF

Download ABB ACS55 Speed Controller Set Up Instructions, PDF

Download ABB ACS55 Speed Controller Set Up Instructions, PDF

Download Automation Direct GS1-20P5 Speed Controller Set Up Instructions, PDF

Download Automation Direct GS1-20P5 Speed Controller Set Up Instructions, PDF

Download Automation Direct GS10 GS11N-20P5 Dura Pulse Speed Controller Set Up Instructions, PDF

Download Automation Direct GS10 GS11N-20P5 Dura Pulse Speed Controller Set Up Instructions, PDF